Omer FOX65CTSMX 14,000 Lb Electro-Hydraulic Alignment Scissor Lift (Above Ground)

Couldn't load pickup availability

Sharing is caring, right? Share this product or our store on your social media! 😃

The platform runways are rigid and built to resist deflection regardless to vehicle's wheelbase or weight distribution; this translates in precise alignment readings. Thanks to its innovative master/double slave hydraulic system, the synchronization between runways is granted with the greatest precision. The pivot points are manufactured for longevity, incorporating an anti-rotation system, self-lubricating bushings, and zerk grease fittings, all designed to increase longevity and allow for years of trouble free operation. The drive-on ramps remain attached to the platforms when the lift leaves the ground, maximizing the shop floor. Their length allows even the lower-profile vehicles to get on the lift.

The Fox 65 is ALI Certified and built to the highest safety standards. Multiple safeties are built within the system including parachute valves, mechanical safety devices, automatic insertion, photocells to control the synchronization of the runways, micro-switch with an acoustic buzzer to complete the lowering process, low voltage controls (24v), and “deadman” controls.

A hot-dipped galvanization of the whole structure of this lift can be added as an option, offering extra protection from corrosion due to water or salt exposure, and dramatically extending the life of the equipment.

Features

- Built to a higher standard of quality; made in Italy by O.ME.R S.p.A., a world leader in Lift Manufacturing for over 40 years in an ISO 9001 facility.

- Incorporating a minimal footprint, extending the use of the shop floor and giving uninhibited vehicle access for the operators.

- Platform Runways are rigid and built to resist direction regardless to vehicles wheelbase or weight distribution – this translates in precise alignment readings.

- Thanks to the innovative master/double slave hydraulic system, synchronization between runways is granted with the greatest precision.

- The drive-on ramps remain attached to the platforms when the lift leaves the ground, maximizing the shop floor. Their length allows even the lower vehicles to get on the lift.

- The pivots points are manufactured for longevity, incorporating an anti-rotation system, self-lubricating bushings and zerk grease fittings.

- ALI Certified and built to the highest safety standards.

- Multiple Safeties within the system including parachute valves, mechanical safety devices, automatic insertion, photocells to control the synchronization of the runways, microswitch with an acoustic buzzer to complete the lowering process, low voltage controls (24v), and “deadman” controls.

- Hot-dipped galvanization of the whole structure as an option, offering extra protection from corrosion due to water or salt exposure, and dramatically extending the life of the equipment.

Specifications

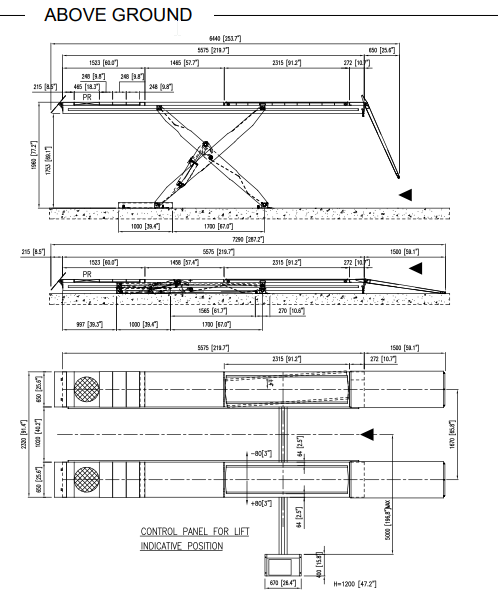

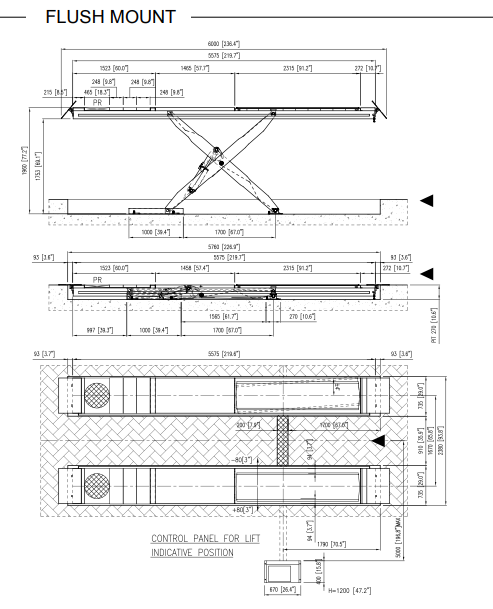

| Capacity | 14,000 LB. / 6.5T |

| Overall Platform Length | 219.7" / 5575 mm |

| Platform Width | 25.6" / 650 mm |

| Collapsed Height | 10.4" / 265 mm |

| Raised Height | 77.2" / 1960 mm |

| Overall Length (Surface Mounted) | 287.2" / 7290 mm |

| Length of Rear Slip Plates | 89.4" / 2270 mm |

| Maximum Service Wheel Base | 185 " / 4700 mm |

| Maximum Wheelbase for 4 wheel alignment | 185 " / 4700 mm |

| Noise Level | < 75 decibels |

| Power Requirement | 2.2 Kw 220 V / 1 phase |

| Shipping Weight | 6170 lbs / 2800 kg |